In today’s automobiles, it has become an inevitable development trend that plastics are widely used in automobiles instead of expensive metal materials. High-strength engineering plastics not only reduce the cost of parts processing, assembly and maintenance, but also make vehicles lighter, energy-saving and environmentally friendly. The data shows that plastics and their composite materials are the most important lightweight materials for automobiles. They can not only reduce the mass of parts by about 40%, but also reduce the procurement cost by about 40%. Therefore, their usage in automobiles has risen rapidly in recent years. .

Opportunities and challenges of engineering plastics

In the 1990s, the average amount of plastic used in automobiles in developed countries was 100kg/vehicle-130kg/vehicle, accounting for 7%-10% of the curb weight of the whole vehicle; by 2011, the average amount of plastics used in automobiles in developed countries reached more than 300kg/vehicle, It accounts for 20% of the curb weight of the whole vehicle; it is estimated that by 2020, the average amount of plastic used in automobiles in developed countries will reach more than 500kg/vehicle.

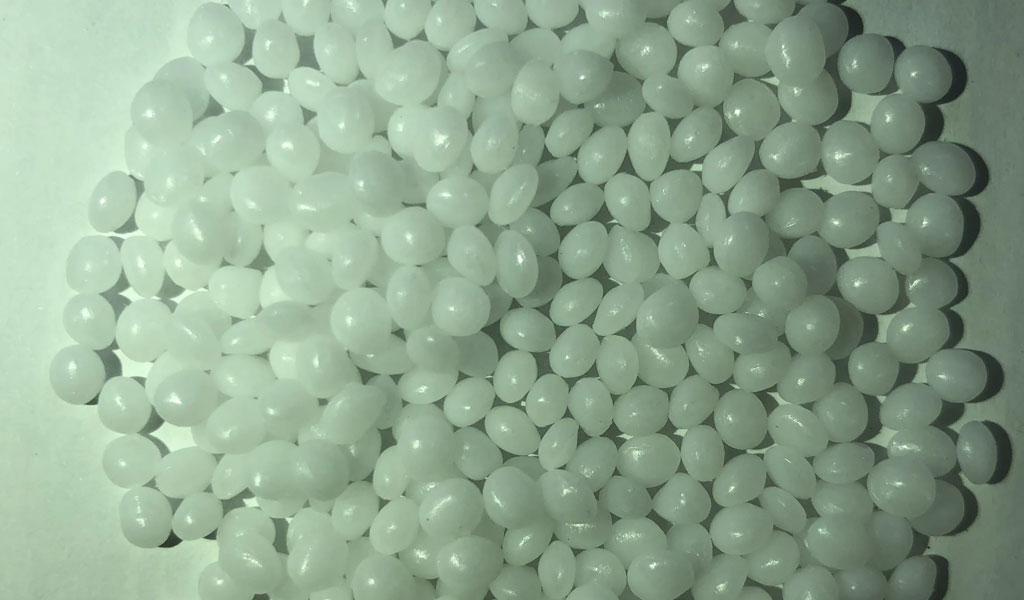

At present, the most widely used general-purpose plastics in automotive plastics are polypropylene (PP), ABS resin, polyvinyl chloride (PVC) and polyethylene (PE). Polyolefin materials constitute the main plastic parts of automobiles, and this trend will become more and more obvious in the future. Below, the author will list several mainstream automotive engineering plastics solutions and interpret their characteristics.

Polypropylene (PP)

PP can be used as a variety of auto parts, and now in a typical passenger car, PP plastic parts account for more than 60. The main varieties of PP auto parts are: bumpers, instrument panels, door trim panels, air conditioner parts, battery shells, cooling fans, and steering wheels, of which the first five account for more than half of the PP consumption in the entire vehicle.

Polyethylene (PE)

A series of modified PE alloy materials with good flexibility, weather resistance and coating performance are obtained through graft modification and filling and toughening modification of high-density PE and low-density PE resins. PE mainly uses blow molding to produce fuel tanks, ventilation pipes, deflectors and various storage tanks.

In recent years, the amount of PE in automobiles has basically not increased. It is worth noting that the development trend of lightweight automobiles has promoted the plasticization of fuel tanks. Plastic fuel tanks are officially used in European cars, and their main material is high molecular weight high density polyethylene (HMWHDPE).

ABS resin

ABS resin is a terpolymer of three monomers of acrylonitrile, butadiene and styrene, which can be used to make exterior or interior parts of automobiles such as instrument housings, refrigeration and heating systems, tool boxes, armrests, radiator grilles panels, etc.; it can also be used to make dashboard skins, trunks, glove box covers, etc.

In recent years, the increase in the amount of ABS resin used in automobiles is not very large. This is mainly because the competition between ABS resin and PP resin is very fierce, and ABS itself also has defects such as poor weather resistance, discoloration and flammability, so it is used in automobiles. Applications in major components such as car dashboards, grilles, etc. are also limited.

Polyamide (PA)

Polyamide, commonly known as nylon, has high impact strength, friction and wear resistance, heat resistance, chemical resistance, lubricity and dyeing properties. As automotive structural parts, the amount of PA is increasing and can be used in the harsh environment around the engine.

Polyoxymethylene (POM)

It has excellent friction and wear resistance properties, long-term sliding properties, molding fluidity and surface beauty and gloss properties, and is also suitable for insert molding. Automobile chassis bushings, such as steering knuckle bushings, various bracket bushings, front and rear leaf spring bushings, brake bushings, etc., are widely used POM type three-layer composite materials. It is based on cold-rolled steel plate and sintered porous bronze The powder is the intermediate layer, and the surface is covered with modified polyoxymethylene as a three-layer composite material for the anti-friction layer. And rolling out a certain regular oil storage pit, its structure determines its special properties: it not only has the mechanical strength and rigidity of steel, but also has excellent anti-friction and anti-wear properties under the condition of boundary lubrication. Other applications include door handles, seat belt mechanics, combination switches and mirrors.