3D printing can now 3d print metal materials. Many metal products are produced in small batches, and some friends will choose 3D printing. Metal 3D printing is basically charged based on the weight of the material. Calculated on a gram basis, the metal materials are now mainly stainless steel. And aluminum alloy, 3 yuan to 8 yuan per gram, specific drawings and quotations must be provided, the price is very transparent.

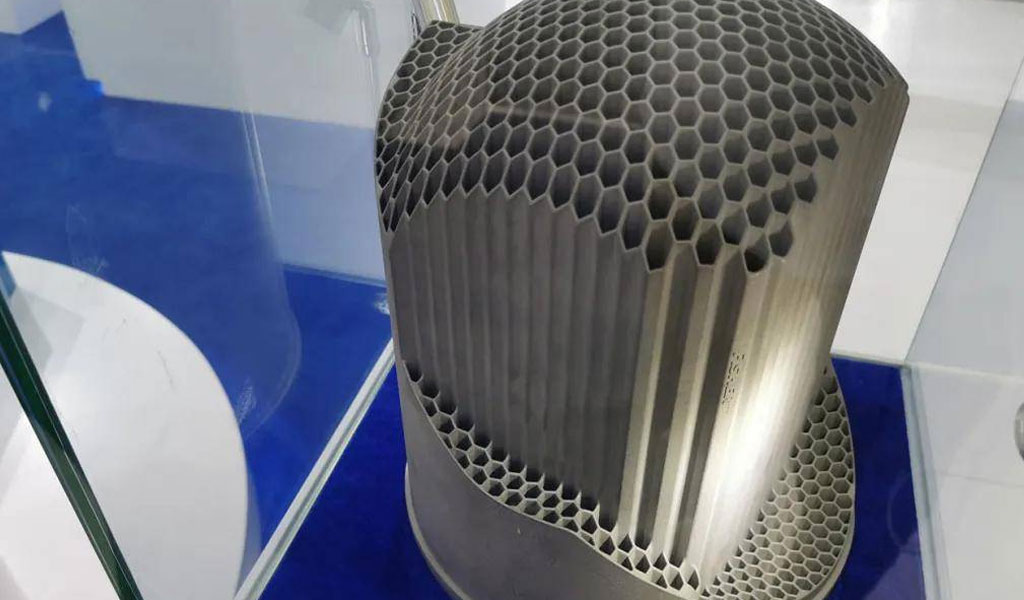

Metal 3D printing is a 3D printing technology that uses metal powder to directly print metal parts, also known as metal powder sintering (SLM).

When printing, the scraper spreads a layer of metal powder on the base plate of the forming cylinder, and the laser beam will selectively melt the powder according to the cross-sectional profile of each layer of the part to process the current layer. After one layer of sintering is completed, the lifting system lowers the height of one cross-section layer. The powder spreading roller spreads another layer of metal powder on the formed cross-section layer and sinters the next layer. This is done layer by layer until the entire part is sintered.

At present, the printing layer thickness of metal 3D printing is generally 0.04-0.10mm, with high precision; the density of sintered metal parts can reach 99% of the density of cast metal parts, with good strength; the printing cycle is 5-7 days, which is short.

1. Stainless steel

It has good corrosion resistance and high strength, and can quickly and efficiently produce small batches of complex industrial parts.

Stainless steel is the cheapest metal printing material and has high metal 3d printing service cost performance.

2. Aluminum alloy

It has good specific strength and is widely used in spacecraft manufacturing, mechanical equipment, transportation and other fields.

Traditional manufacturing technology wastes materials and takes a long time to process. Using metal 3D printing technology can effectively reduce material waste and shorten processing time. Moreover, metal 3D printing cost has absolute advantages for some complex structures that are difficult to achieve with traditional processes.