Delrin Laser cutting is a technology that uses a laser to cut a 2D design into a physical object from delrin plastic materials. Laser cutting is ideal for knife making because it is inexpensive and offers outstanding accuracy and precision without compromising quality. Knife manufacturers and knife makers use it to cut knife blanks and parts out of sheets of delrin.

Delrin Laser Cutting For Pipe,Tube,Plate,Sheet

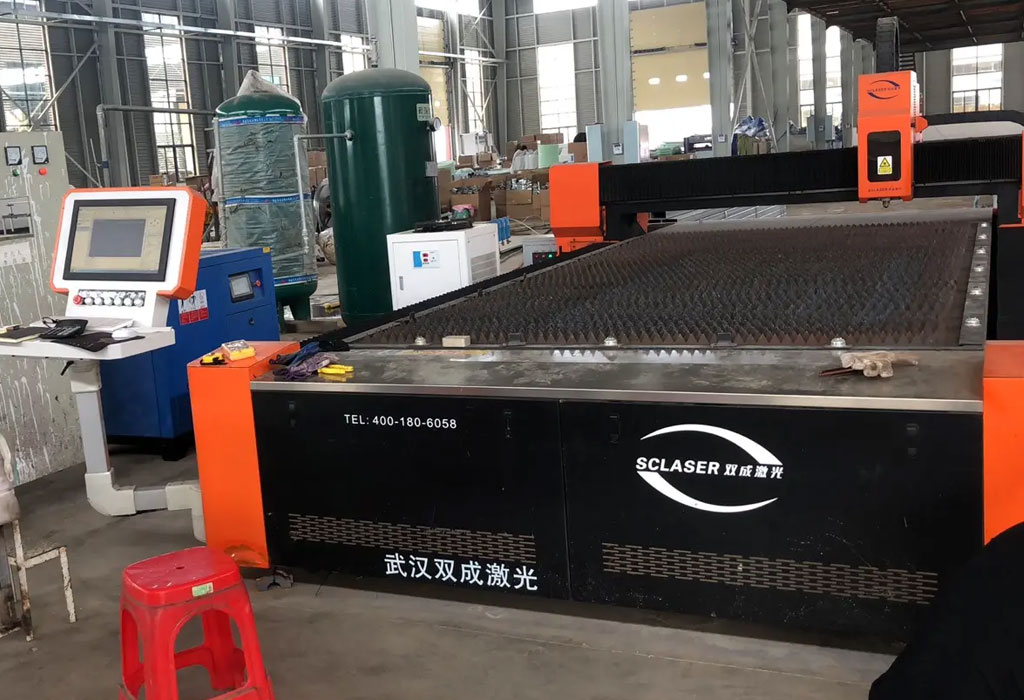

Highly repeatable production, a wide range of delrin cutting capabilities, and a quick turnaround time are what it takes to become a premier CNC laser cutting service. Our China-based facility has perfected these requirements and more. We have only the most advanced laser cutting machinery to complete your project accurately and efficiently. Whether your project is a single item or an entire assembly line of parts, you’ll see the consistent quality we produce every time.

Our Delrin Laser Cutting Service

- Custom Laser Cutting

- Fiber-optic Laser

- Custom Laser Engraving

- Laser Marking

- Etching

- Design Help

Our CNC laser cutting service portfolio has an extensive library of repeat customers and successful results. Our tight tolerance allows us to meet the toughest standards, which are critical for the medical and military industries.

When talking about Delrin plastic products, many people think of buckets, baskets, pots and so on sold by roadside stalls. With the development of science and technology, Delrin plastic products are not only used in the above products, but also in high-tech fields such as automobiles, electronics, medical equipment, and even aerospace. However, in order to be applied in these high-end fields, Delrin plastic material itself must not only meet the requirements of laser cutting, but also solve the problem of laser printing, and how to achieve accurate, clean, fast and efficient in welding, cutting, engraving and drilling process The problem. Laser cutting Delrin plastic processing has the following advantages:

- Intelligent control, automatic control, precise positioning, one-time forming, smooth edge. Compared with traditional technology, the product is more beautiful, efficient and material saving.

- In the process of cutting and engraving, the laser does not touch the surface of the object to ensure the quality of each product and improve the competitiveness of the enterprise;

Vaporization Cutting

A focused beam heats the surface of the material to its boiling point, creating a keyhole. Occlusion causes a sudden increase in absorption and rapid deepening of the pores. The holes are deepened, and the steam generated during boiling erodes the molten wall and sprays out a spray, which further enlarges the holes. Non-melting materials, such as wood, carbon, thermoset Delrin plastic, are often cut this way.

Melt

Molten Delrin material is blown from the cutting zone by high pressure gas, greatly reducing the power requirements for the molten material. First heat the material to the melting point, and then blow the molten material to avoid further raising the material temperature. The Delrin material so cut is usually metal.

Thermal Stress Cracking

Brittle materials are particularly sensitive to thermal fracture, one of the hallmarks of thermal stress cracking. The concentration of light on the surface causes localized heating and thermal expansion. This creates cracks, which are then guided by moving beams. Cracks can move in the order of m/s. It is usually used to cut glass.

Stealth Dicing Of Silicon Wafers

Using silicon semiconductor devices to separate microelectronic chips from silicon wafers, a so-called stealth dicing process can be used. Using a pulsed Nd:YAG laser with a wavelength of 1064 nanometers, it is very suitable for the electronic band gap of silicon (1.11 electron volts or 1117 nanometers).

Reactive Cleavage

Also known as combustion stabilized laser cutting and flame cutting. Reaction cutting is like oxygen torch cutting, but the laser beam is the ignition source. Suitable for cutting carbon steel with thickness greater than 1mm. This method allows relatively low laser power to cut very thick steel plates.