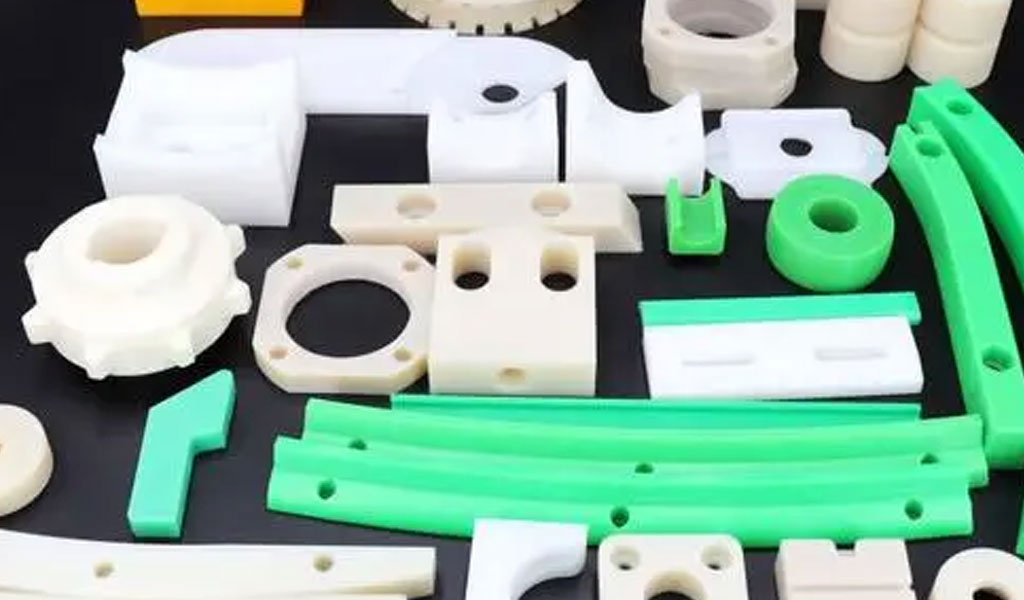

Engineering plastics – MC nylon slider, replace steel with plastic, and use CNC machining center to punch holes with high precision! MC nylon sliders are anti-vibration, impact-resistant and wear-resistant. It is a trend to replace metal materials.Nylon CNC machining centers can mill and punch holes! MC nylon sliders are engineering plastics. Substituting plastic for steel and excellent performance are the biggest features of MC nylon sliders. MC nylon slider has the characteristics of high strength, light weight, anti-corrosion, wear resistance, high strength, insulation, etc., and is widely used in agricultural and industrial fields. MC nylon slider is an indispensable part.

The friction coefficient of MC nylon slider is 8.8 times lower than that of steel, 8.3 times lower than that of copper, and its specific gravity is only 1/7 of that of copper. It is precisely because of these advantages that MC nylon sliders have gradually replaced metal. MC nylon slider is just one of the product forms, and cast MC nylon is also made into guide rails, supporting wheels, worm gears, gears, bushings, bearing bushes, pins and other products. Casting MC nylon instead of metal greatly reduces the material cost and prolongs the service life, so it is a very wise choice.

Application of MC nylon slider

MC nylon sliders are mainly used in electrical parts, automobile manufacturing parts, and chemical equipment, such as sliders for the support of the boom of automobile cranes. We used brass materials before. After switching to MC nylon, its service life is improved. It is 4~5 times higher, and it can maintain the lubrication characteristics for a long time after refueling. At the same time, it also has the advantages of low noise, fatigue resistance, vibration resistance, impact resistance, and wear resistance.

The difference between MC nylon slider and ordinary nylon

There are more MC nylon sheets than ordinary nylon sheets, so they gradually replaced ordinary nylon sheets. MC nylon board has more advantages than ordinary nylon (polyamide PA),

- 1. MC nylon plate material has higher mechanical strength, greater toughness, and better wear resistance. In addition, it has the advantages of corrosion resistance, water resistance, high melting point, and mud oil;

- 2. The production cost of MC nylon board material is low, and the service life is long;

- 3. The dimensional stability of MC nylon plate material is relatively good, and it has the advantage of self-lubrication, and the size of the product is not limited.

Nylon material itself has a high stress, so it is difficult to control the water absorption rate of nylon material during processing. The size produced by spraying cutting fluid is different from the size after cleaning and drying. If it is air-cooled, the heat at the tip of the tool is high, and the size can be accurately controlled! It is easy to deform. Because the piece in the video is relatively small, it cannot be clamped with a pressing block. The customer used to clamp it with glue, which has low efficiency and a relatively high defect rate.

The process we recommend to customers is to dehumidify the nylon material first, so that the material is not easy to crack, and the processed parts are also difficult to break!

Then use the frozen suction cup for seepage cooling and clamping, and choose a sharp-edged white steel knife. During the processing, there is no need to pour cutting fluid, and the processing heat can also be well released to improve the machinability of the material. MC nylon sliders are made of Hasf HASSFULL-MF1325 engineering plastic machining center can realize rough machining, semi-finish machining and finish machining. This equipment can mill slots and drill holes for MC nylon sliders. This equipment is suitable for materials with a maximum size of 1300×2500mm. The X/Y/Z axis positioning accuracy and X/Y/Z axis repeat positioning accuracy are ±0.02mm, which is completely sufficient for the processing of MC nylon sliders.